A thank you for your loyalty

We say THANK YOU! For a limited time, you'll receive a Wera Kraftform VDE screwdriver + bottle opener free with your order of €750 or more! Only while stocks last.

We will be happy to help you with your selection & technical questions.

+49 201 749189-21

We say THANK YOU! For a limited time, you'll receive a Wera Kraftform VDE screwdriver + bottle opener free with your order of €750 or more! Only while stocks last.

Do you need support cross-referencing your sensors? No problem, we offer a full cross-referencing service!

Book now

Subscribe to our newsletter and receive a 10%* coupon!

Go to subscriptionYou can unsubscribe from the newsletter at any time. Your data will not be passed on. More about the data protection regulations.

Cloud compatible

Cloud compatible Cloud compatible

Cloud compatible Cloud compatible

Cloud compatible Cloud compatible

Cloud compatible Cloud compatible

Cloud compatible Cloud compatible

Cloud compatibleExplanations of technical terms, technical resources and interesting facts about sensors and automation.

Every day, we supply thousands of people and machines with trendsetting sensor technology and automation systems. Learn more about who is behind autosen.com.

Don't miss any more news and exclusive offers! Sign up now for our newsletter and receive regular updates about our products, promotions and events.

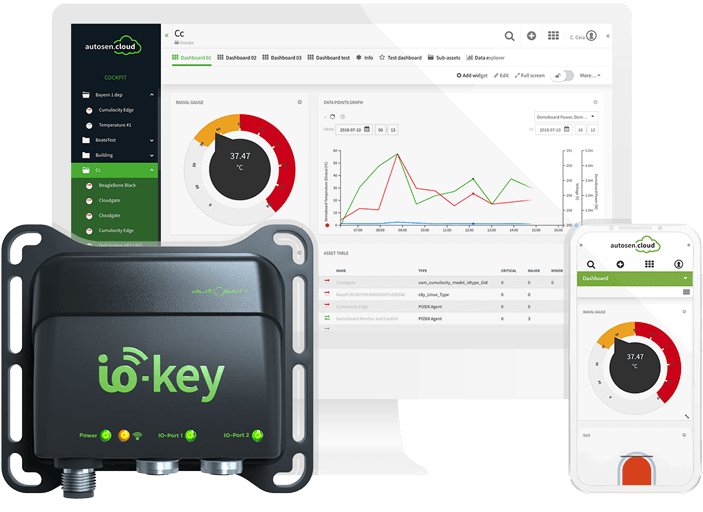

Follow the route of data to the cloud - and learn how we established actual plug&play in the industry.

Cloud compatible

Cloud compatible Cloud compatible

Cloud compatible Cloud compatible

Cloud compatibleProviding thousands of people and machines with the sensors and automation systems of the future!

We are convinced of our products and offer a 5-year warranty on all our catalogue products.

Orders placed before 2 pm will be shipped from our warehouse on the same working day. Orders from non-EU countries will be shipped on the next working day at the latest.

Tens of thousands of highly satisfied customers rely on our technical advice and support by phone or email. Discover our first-class service!

Up to 50% cheaper than other suppliers – get a 5.5% direct discount when ordering online!

Business customers can pay conveniently by invoice from their very first order in many countries. Discover our flexible payment options!

Didn't find what you were looking for right away? Return your order within 30 days and we will refund the purchase price.

"Sensors play a key role here."

"With autosen we chose a provider that guarantees fast delivery even for a small volume order."

"When the safety of children is at stake, reliability and durability come first in the requirements specification."

Whether you are an electrician, an engineer or a mechanical engineer: the ideal automation technology for your systems and machines is essential to meet all the requirements. And thus also finding the right partner for sensor technology and process automation. Welcome to autosen - your search is over!

Our constantly growing product portfolio comprises around 600 products from the fields of position sensor technology, process sensor technology, condition monitoring, IO-Link and IIoT. The range is completed with a selection of suitable connection technology, sensor cables, machine lamps, signal towers and accessories matched to the different sensor types. Find all of this and more in our clearly organised shop, where we do our very best every day to make your shopping experience as enjoyable as possible.

Go to our products

Easy product selection. Highest product quality. Low prices. Items ordered before 2 pm dispatched on same working day. 30-day right of return. 5-year warranty. Outstanding reliability. Still not convinced? Take a look at our customers and read their success stories or trust the thousands of 5-star reviews from satisfied customers. We don't leave customers on their own after they've purchased products - for us, that's where the relationship really begins.

Do you have any questions or cannot find the right product for your application? Give us a call, or use the contact form or our callback service. Our competent staff will be happy to help you – we will find the right solution.

Discover more about usYou can unsubscribe from the newsletter at any time. Your data will not be passed on. More about the data protection regulations.

No longer just buzzwords, but THE key elements for the future of factory automation and process automation. Together, they create the foundations for efficient, flexible and intelligent production. Companies that focus on this are better positioned to overcome the challenges of modern manufacturing and to take advantage of the opportunities offered by digitalisation. Today's customers and markets expect increased customisation, faster delivery times and more sustainable production methods. The technologies mentioned enable a response to these requirements. Through the integration of smart sensors, IIoT and Industry 4.0, companies can optimise their production processes, increase efficiency and reduce operating costs at the same time.

Smart sensors in IIoT provide real-time data on the condition of machines and processes. This enables data-driven decision-making and preventive maintenance to minimise downtime. The networking and intelligence of IIoT and Industry 4.0 enable flexible and adaptable production. Companies can react quickly to changes in demand or production requirements. By continuously monitoring and analysing production data, companies can improve the quality of their products and reduce rejects. Companies that successfully implement these technologies are able to offer innovative solutions and strengthen their competitiveness in an increasingly digitalised environment. autosen supports you in this endeavour, as working together is the only way to embark on a successful future!

Discover IIoT productsAutomation technology is a field of engineering and information technology that deals with the development, implementation and optimisation of systems and processes for the automatic control and regulation of technical processes. The aim is to minimise human intervention in industrial and technological processes in order to increase efficiency, precision, productivity and safety. Automation technology encompasses various technologies and methods:

Automation systems:

Systems for controlling and monitoring processes. This can include the implementation of software, hardware and sensors for collecting and processing data.

Programmable logic controllers (PLCs):

Intended for the automation of machines and systems. PLCs enable the programming of logic and sequences for various applications.

Industrial robotics:

Use of robots and automated systems for tasks such as assembly, packaging, material transport and other industrial processes.

Sensors and actuators:

Integration of sensors for capturing environmental data and actuators for implementing control signals. This enables feedback and the control of processes.

Process control engineering:

Development of control systems for monitoring and controlling industrial processes. This includes the visualisation of process data and interaction with operating personnel.

Machine and system automation:

Automation of production processes, production systems and machines in order to improve efficiency, accuracy and quality.

Integrated systems and networking:

Integration of various automated systems and networking of devices via communication protocols, such as the Industrial Internet of Things (IIoT).

Process optimisation and control engineering:

Application of control engineering to optimise processes and to ensure compliance with specified parameters.

Automation technology is used in various industries to optimise processes, increase efficiency and improve the quality of products and services. Continuous development in the fields of electronics, IT and robotics means that automation technology plays a key role in cutting-edge industry and technology.

Automated production lines and robots are used for assembly, testing, packaging and other production processes to increase efficiency and precision.

Automation technology enables the precise control of chemical processes, dosing of materials and monitoring of response conditions in laboratories and production systems.

In the energy industry, automation technology is used to optimise the operation of power plants, the control of power grids and the monitoring of renewable energy generation systems.

In automotive production, robots and automated systems are used for vehicle production, spraying, assembly and testing.

Automated conveyor belts, warehouse robots and automated vehicles are used in logistics centres and warehouses to optimise the flow of materials and to manage stock levels.

Automation technology plays a key role in aircraft manufacturing, aircraft and spacecraft monitoring and aviation maintenance.

In hospitals and laboratories, automation technology is used to control medical equipment, laboratory processes, surgery robots and pharmacy automation.

Automation technology is used to control heating, ventilation, air conditioning systems, lighting, security systems and other building functions in commercial and industrial facilities.

Automation technology supports food production and processing through the use of automated production systems, sorting and packaging robots as well as monitoring systems.

Automation technology plays a role in the telecommunications infrastructure, particularly in the monitoring and control of networks, data centres and communications equipment.

Automated production lines and robots are used for assembly, testing, packaging and other production processes to increase efficiency and precision.

Automation technology enables the precise control of chemical processes, dosing of materials and monitoring of response conditions in laboratories and production systems.

In the energy industry, automation technology is used to optimise the operation of power plants, the control of power grids and the monitoring of renewable energy generation systems.

In automotive production, robots and automated systems are used for vehicle production, spraying, assembly and testing.

Automated conveyor belts, warehouse robots and automated vehicles are used in logistics centres and warehouses to optimise the flow of materials and to manage stock levels.

Automation technology plays a key role in aircraft manufacturing, aircraft and spacecraft monitoring and aviation maintenance.

In hospitals and laboratories, automation technology is used to control medical equipment, laboratory processes, surgery robots and pharmacy automation.

Automation technology is used to control heating, ventilation, air conditioning systems, lighting, security systems and other building functions in commercial and industrial facilities.

Automation technology supports food production and processing through the use of automated production systems, sorting and packaging robots as well as monitoring systems.

Automation technology plays a role in the telecommunications infrastructure, particularly in the monitoring and control of networks, data centres and communications equipment.

Do you have any questions? Just give our customer service

Do you have any questions? Just give our customer service

The connection between sensors, automation technology and the Industrial Internet of Things (IIoT) lies in their integrated application to create intelligent, networked and autonomous systems in industrial environments. Sensors continuously record data from the environment. In industrial applications, this can be temperature data, pressure measurements, vibrations, humidity values and much more. This data is used to monitor the condition of machines and processes. The collected sensor data is forwarded to automation systems in real time. These systems can make decisions based on the data and automatically execute actions to optimise processes or react to changing conditions. For example, the temperature in an industrial furnace can be controlled automatically. The IIoT enables the networking of sensors, automation systems and other devices. Sensor data can be transmitted wirelessly or via wired networks to central control systems or cloud platforms. This enables processes to be monitored, analysed and controlled centrally. The IIoT makes it possible to analyse large amounts of data (big data) in real time. This data analysis can be used to identify patterns, predict maintenance requirements, optimise processes and improve efficiency.

The seamless connection between sensors, automation technology and IIoT creates an intelligent, networked infrastructure that helps companies to make their production more efficient, reduce costs, improve quality and respond flexibly to changing requirements.

Go to our productsSensors are devices that detect physical or chemical properties of the environment and convert them into electrical signals. In automation technology, sensors are used to collect data on the condition of machines, environments or processes. This data can include parameters such as temperature, pressure, speed, position and many others.

Automation technology uses sensor data to control and monitor automated processes. By programming control systems, machines and systems are controlled in such a way that they function optimally and efficiently. Sensors play a crucial role here, as they provide the feedback and real-time information needed to automate processes.

The IIoT refers to the networking of devices, sensors, machines and systems in industrial environments via the Internet. The IIoT extends conventional automation by enabling bidirectional communication between the various components and collecting and analysing large quantities of real-time data.

Order now

Order now