Ultrasonic sensors

Ultrasonic sensors detect objects of varying material types and levels of liquids and bulk materials without contact and at a long range. Further, transparent, highly reflective and high-contrast objects can be detected. The sensor detects objects using ultrasonic waves according to the principle of travel time measurement and is resistant to soiling. Read more here

Ultrasonic sensors

What is an ultrasonic sensor? How do ultrasonic sensors work and for which applications are they used? What has to be observed when using ultrasonic sensors? You will learn (almost) all about ultrasonic sensors in the following.

What is an ultrasonic sensor?

Ultrasonic sensors detect objects and liquids with the aid of ultrasonic waves and calculate the distance to the object according to the principle of travel time measurement. They are used when large detection ranges are involved. In applications in which photoelectric sensors reach their limits of capability, ultrasonic sensors are the solution. The sensors operating according to the ultrasonic principle can reliably detect transparent, strongly reflecting, and contrast-rich objects. Ultrasonic sensors from autosen are available as ultrasonic sensors and ultrasonic probes. They differ as to their outputs and IO-Link compatibility.Typical applications of ultrasonic sensors

Ultrasonic sensors are used for example when working with:- Glass

- (Transparent) liquids

- Films/foils

- Items that can tear (detection)

- Quality inspection

- Empty tank detection

- Level measuring

- Position monitoring

- Degree of filling in supply of parts

- Presence detection

- Monitoring of load carriers

- And in general for objects in solid, liquid, granular or powdery state which are transparent, semi-transparent or optically difficult to detect

Double-sheet detection

Level measuring

Quality inspection

Deflection surface

Monitoring of load carriers

Volumetric flow

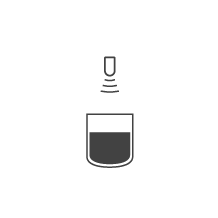

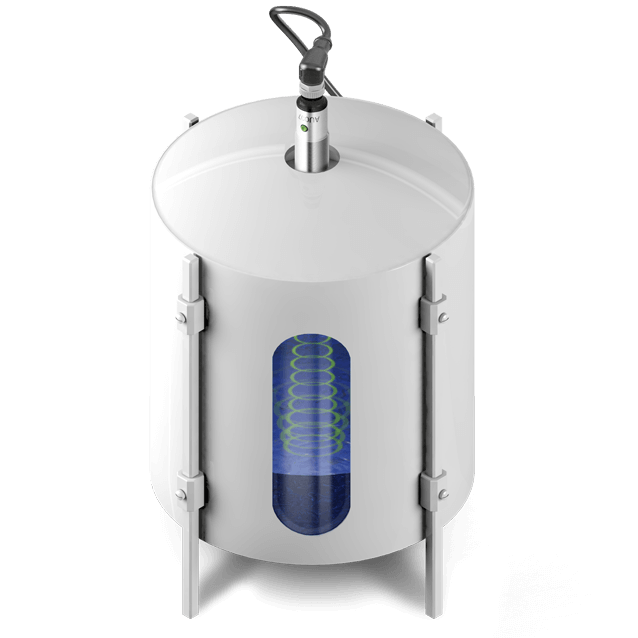

Ultrasonic sensors for level measuring

Level measuring using ultrasonic sensors is one of the continuous measurement methods. The sensor is mounted at the top inside the tank and emits ultrasonic pulses reflected by the surface of the medium. The device calculates the distance to the surface and thus the filling level from the travel time from sending the pulse up to pickup of the echo.

Ultrasonic level sensors measure levels up to 8m contactless for:

- Liquids

- Paste-like media

- Powder

- Bulk materials

How ultrasonic sensors work

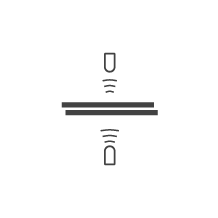

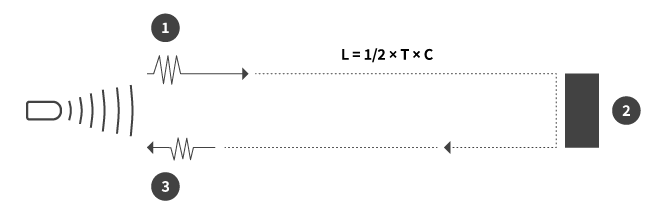

Ultrasonic sensors contactless detect objects and fill levels by generating a short high-frequency ultrasonic pulse by an oscillating ceramic and cyclically emit this pulse. The pulse is propagated in the air at supersonic speed. If the sound pulse hits an object, it is reflected by it and the echo is detected by the sensor. The distance between sensor and object is calculated by the sensor according to the travel time measurement principle from the time span between emission of the signal and reception of the echo. By measuring the distance using the travel time measurement instead of measuring intensity, ultrasonic sensors are characterised by excellent background suppression.

Ultrasonic sensors can detect objects of almost any material reflecting sound and with all properties, such as glass, wood, metal, plastic, liquids and even thin films with the aid of this measuring principle. Difficult working environments, such as dust, vapour, dirt or paint vapours have no influence on ultrasonic sensors.

Ultrasonic sensors can detect objects of almost any material reflecting sound and with all properties, such as glass, wood, metal, plastic, liquids and even thin films with the aid of this measuring principle. Difficult working environments, such as dust, vapour, dirt or paint vapours have no influence on ultrasonic sensors.

L = distance, where T is the time between emission and reception and C the supersonic speed.

Ultrasonic sensors: Advantages and disadvantages

Ultrasonic sensors in practice: What needs to be observed?

When you selected the appropriate ultrasonic sensor for your application, it has to be installed correctly in your application to ensure best possible functioning. This section gives a brief and clear overview about what has to be observed.Installation of ultrasonic sensors

Ultrasonic sensors can be installed in each position if the following conditions are fulfilled:- Deposits on the area active to sound are avoided

- When using several ultrasonic sensors the minimum distances have to be complied with (see operating instructions) to prevent reciprocal influencing and faulty switching

Deflections using sound deflection angles

The sound deflection angles can be used to deflect the sound beam of the sensor. However, multiple deflections shorten the range of the sensors and should therefore be avoided.Influences by object properties

Hard and level materials and objects are best suited for using ultrasonic sensors because the sound pulses are reflected very well and properly. If you want to use ultrasonic sensors however, there are some additional aspects to be considered with regard to the object properties.Alternatives of ultrasonic sensors

Instead of ultrasonic sensors it is also possible to use photoelectric sensors, inductive sensors (magnetic metals only) or capacitive sensors can for position detection and presence detection.For level measuring, you can also use our level sensors, capacitive sensors, pressure sensors and photoelectric sensors.

Cloud compatible

Cloud compatible