Correction factors for inductive sensors

Correction factors for inductive sensors – Factor 1

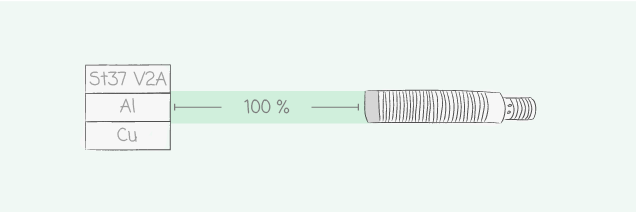

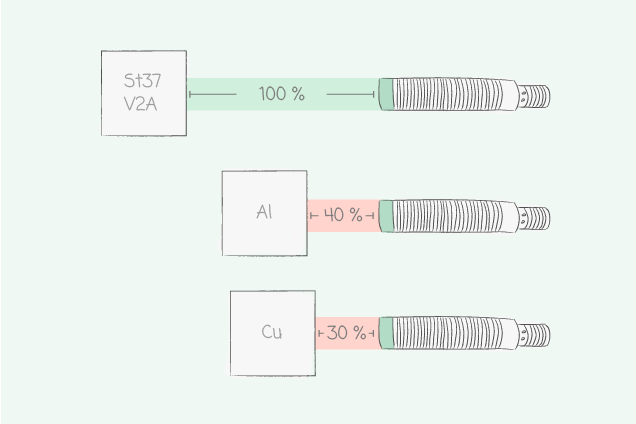

What is meant by 'reduction factor' or 'correction factor' in the context of inductive sensors? Explanation: Inductive sensors respond to metals. The distance between the forward surface of the sensor and the measurement object is referred to as the sensing range. This distance depends on the material of the metal to be sensed. Steel, for instance, is detected significantly better than copper. For this reason, manufacturers specify correction factors or reduction factors in their data sheets. The actual sensing range for individual metals is obtained by multiplying the nominal sensing range by the specified factors. The following table shows the correction factors for the various metals:

Factor 1 sensors have the same sensing range for all metals.

Patrick Targonski, Product Manager at autosen

Advantages of Factor 1 sensors:

- One sensing range for all metals

- Very high switching frequencies

Disadvantages of Factor 1 sensors:

- Higher price

- Double switching may occur