TQ Robotic - Ramp-up with ease

Automation – as efficient and uncomplicated as possible

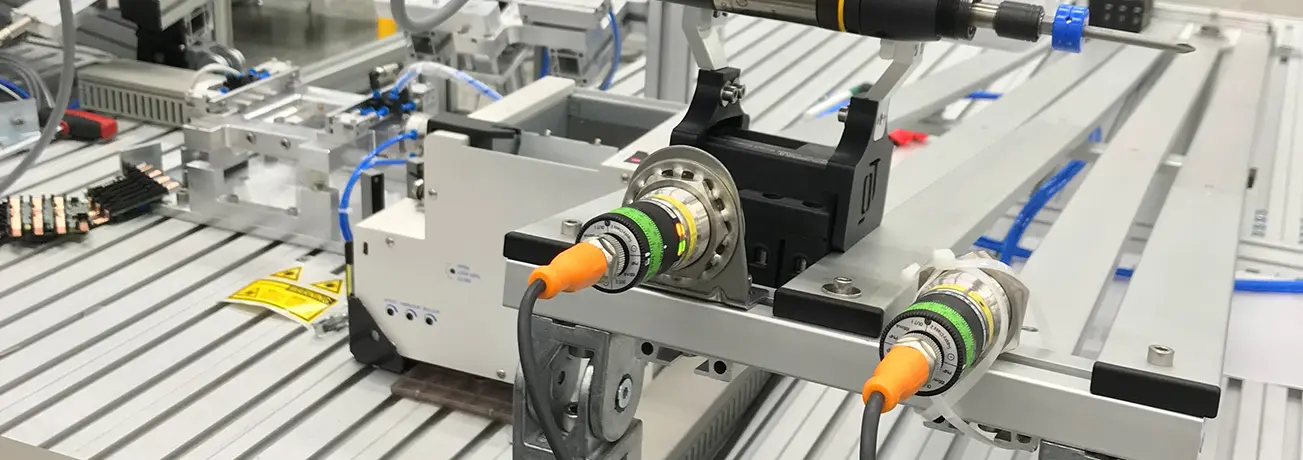

TQ-Group is one of the largest technology service providers and electronics specialists in Germany. The io-key is used in the TQ-Robotics division. This division offers robotics solutions from a single source for external clients and other divisions of the Group. TQ-Robitics focuses on efficient automation solutions that are as uncomplicated as possible and can be seamlessly integrated into corporate processes – the ideal environment for the io-key.

The io-key is the optimal tool for all integrators who value transparency and want to autonomously retrieve decisive information in the critical ramp-up phase.

Robert Vogel, Sales Manager, TQ-Robotics

Digital bypass for the TQ-Robotics ramp-up brings transparency to the commissioning process

Excel or flying blind: Integrators have often only had a choice between two evils when ramping up digitalised systems. As long as the systems are not yet 100% connected, the necessary monitoring of machine performance can only be carried out on site with a lot of staff, or only with a time delay during operation. With the io-key, the automation specialists from TQ-Robotics set up a temporary digital bypass in order to be able to query important data during ramp-up.

In the critical phase shortly before, during and immediately after commissioning, valid data about the performance of a system is essential to detect possible weak points and sources of error in good time. Is the machine running? How much is being produced? Brief questions, long answers, if the path is via the customer's systems and the client's IT. Especially since not every company wants to make this data accessible.

Important data without diversions via the customer network

In these cases, TQ-Robotics uses the io-key and transmits the required information past the customer systems directly into the protected cloud environment. The approach is both pragmatic and effective. If, for example, an entire production line is involved, monitoring of the last unit in the chain is usually sufficient for the ramp-up phase. A single inductive sensor that records the number of units produced can provide the necessary data. Depending on the structural situation on site, installation of the set consisting of sensor and io-key and the initial data transmission take no more than half an hour. This saves a significant amount of time compared to conventional methods or time-consuming readjustments during operation.

Weaknesses, faults and optimisation potentials are identified and addressed via the io-key even before live operation

Everything at a glance

The TQ-Group offers efficient automation solutions in the TQ-Robotics division.

The io-key enables transparency and autonomous data retrieval during ramp-up.

TQ-Robotics uses the io-key as a digital bypass for valid monitoring without a customer network.

By using the io-key, important data can be collected quickly, which obviously saves time and increases efficiency.

Technology service provider and electronics specialist

TQ-Systems GmbH

Gut Delling, Mühlstr. 2, D-82229 Seefeld

info(at)tq-group(dot)com

info(at)tq-group(dot)com

+49 2166 9837-0

+49 2166 9837-0

www.tq-group.com

Products used

More success stories

Get started with the IIoT!

Very simple via io-key® wireless gateway Bring sensor data into the cloud