Pressure sensors

Pressure sensors measure the pressure process variable and convert it into a signal that is then further processed. By measuring the pressure at the bottom of containers/tanks, the level of liquids can also be detected. Our pressure sensors work on a relative measurement principle. Read more here

All about pressure sensors

What does the measured variable pressure stand for and which types of pressure are there?

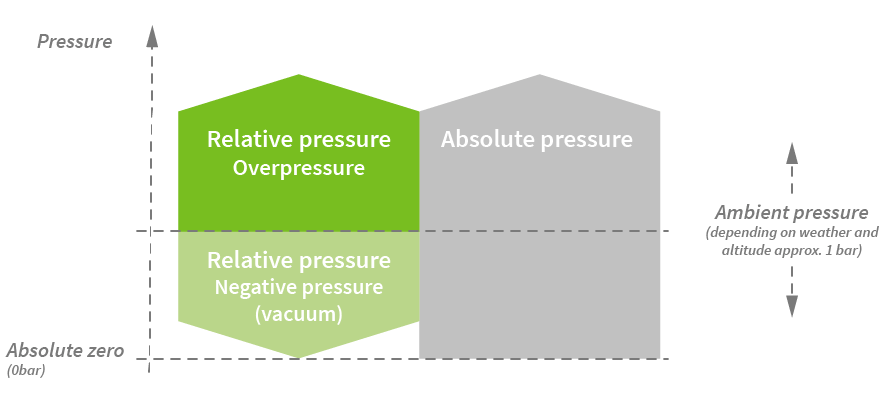

Pressure is a physical measured variable. It describes the force in Newton acting vertically on a surface area of a square metre (p=FN*A). The SI unit for pressure is Pascal. In industrial applications the unit bar is more common, with: 1 bar = 100,000 Pascal. A table for conversion of pressure units is given below.Pressure data always refer to a reference value. The measured pressure corresponds to the difference between the measurement result and the reference pressure. There are the following three types of pressure data: Absolute, relative and differential pressure.

Differential pressure, absolute pressure or relative pressure?

Relative pressure

Relative pressure specifies the pressure measured as a function of the actually present ambient pressure. The atmospheric pressure on earth is 1.013 bar. This pressure results from the weight of the air masses pressing on the earth's surface. The atmospheric pressure varies as a function of the height above sea level and therefore pressure equalisation is required when measuring the relative pressure.

Differential pressure

Differential pressure describes the ratio of two different system pressures, for example the difference of two pressure vessels.

Absolute pressure

Absolute pressure specifies the pressure relative to an ideal vacuum, i.e. a space void of air with the pressure zero bar.

What are pressure sensors and what are they used for?

A pressure sensor - also referred to as pressure transducer - measures the physical process variable pressure and converts it into an electric signal which is further processed. Pressure sensors from autosen measure the relative pressure and are distinguished as electronic pressure sensors, electronic pressure transmitters and electronic pressure switches.Electronic pressure sensors

Pressure sensors from autosen measure the pressure and output it as a 4 … 20 mA analogue signal. In addition they have two switching outputs issuing a binary switching signal as NO or NC contacts if defined limit values are exceeded or fallen below. They have a display of indication of the measured values and for parameterisation. We offer sensors with IO-Link for pressure ranges from -1 to 400 bar.Electronic pressure switches

Pressure switches are suitable for limit value monitoring of system pressures. They issue a binary switching signal if a defined system pressure is exceeded or fallen below. This is to ensure that critical system pressures are in the valid range any time. Pressure switches from autosen have two antivalent switching outputs for measuring ranges from 0 … 400 bar.Electronic pressure transmitters

Electronic pressure transmitters output the measured pressure as a continuous signal. They measure the physical process variable and convert it into an analogue standard signal. You will find pressure transmitters from autosen with analogue output 4 … 20 mA for measuring ranges from 0 … 400 bar.Pressure sensor design

The design of pressure sensors is the same for each measuring principle. The sensor is installed with a process connection such that the medium gets into contact with the measuring cell and the process pressure acts on the measuring cell. The measuring cell converts the pressure into an electric variable which is converted into a standard signal in the integrated evaluation electronics. The sensor outputs the measured value via the electric connection via which it is also supplied with the required operating voltage.How does a pressure sensor work?

Pressure sensors use different functional principles for pressure measurement. Among others, there are the following:- Piezoresistive

- piezoelectric

- capacitive and

- inductive pressure sensors.

Pressure sensors from autosen use piezoresistive and capacitive measuring principles. Stainless steel thick film measuring cells are characterised by a robust and compact design, while the ceramic-capacitive measuring cell is particularly durable.

Ceramic-capacitive measuring principle

Stainless steel thick film or Wheatstone bridge

Advantages/features of a pressure sensor

With a range of different measuring cells and output functions as well as a variety of housing designs, pressure transducers can be used for all industrial processes requiring exact determination of data on pressures in gases or liquids.Highest accuracies, best quality

Insensitive to pressure peaks

Robust and durable

High IP protection rating

Flexible use, broad pressure measuring ranges and vacuum

Plug & Play:

Fields of application

Pressure sensors are used in diverse ranges of application in numerous industries. It is especially in process technology and process engineering that it is crucial to monitor the process pressure to ensure process reliability and the quality of the final product.Typical applications of pressure sensors are:

- vacuum regulation

- measurement of hydrostatic pressures in the food and beverage industry

- measurement of system pressures of oil in hydraulic systems or

- detection of the hydrostatic pressure in tanks.

Conversion table for pressure units

Measuring ranges and rating of pressure sensors

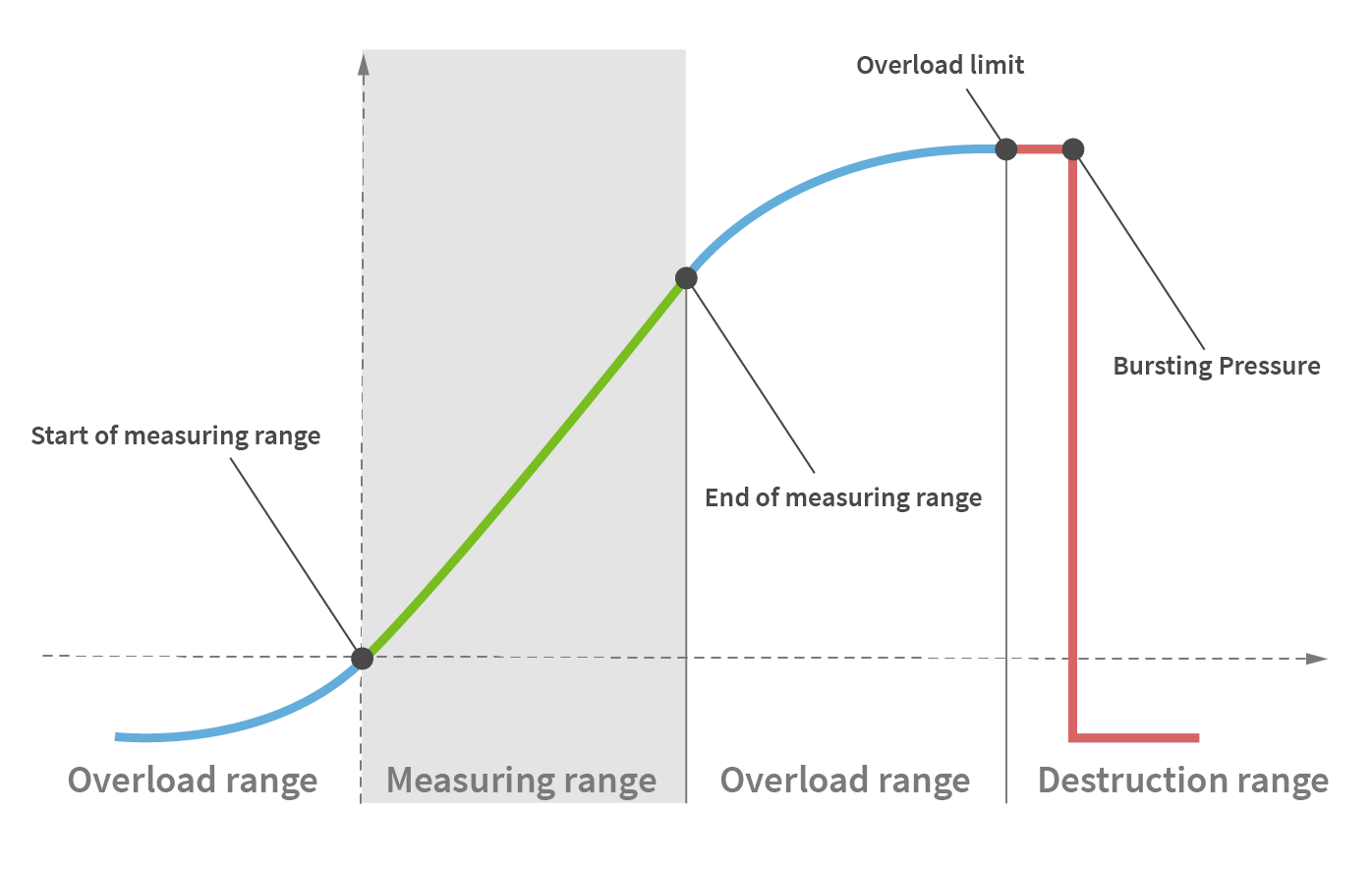

Measuring range:

Overload range:

Destruction range:

It must always be observed when carefully selecting the appropriate pressure sensor that pressure peaks in the destruction range never occur. Reliable measurement according to the data in the data sheet is ensured only in the specified measuring range.

Underload range:

Accuracy data in data sheet

Linearity deviation

Long-term stability

Switching point accuracy

Repeatability

Resolution

Cloud compatible

Cloud compatible