Level monitoring systems

Level sensors for a very wide range of industrial applications

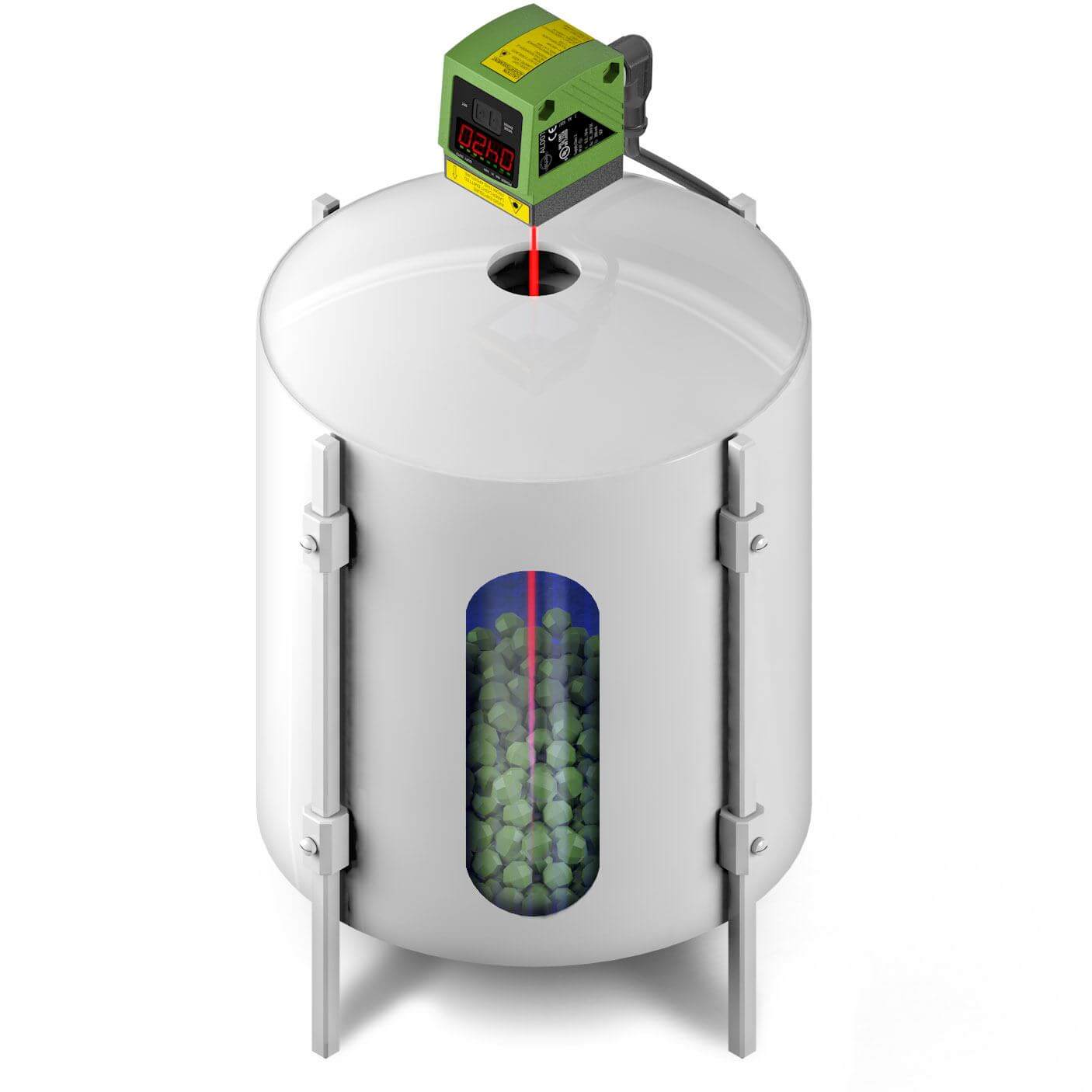

Filling levels can be registered using either a contact or contact-free method. To so do, various sensor techniques are employed. Depending on the actual requirement, the filling level can be determined continuously or as a threshold value. Capacitive sensors can be used for point level monitoring, and they can also detect filling levels through non-metallic container walls. The exact filling level for liquids can be hydrostatically determined using pressure sensors or via a probe with guided wave radar. With bulk material, photoelectric sensors can determine the filling level up to ten metres to the nearest centimetre. The level sensors AF005 and AF006 are particularly reliable, even where material to be sensed tends to cling. The measuring technique in this case is based on impedance spectroscopy.

Point level detection

- For contact with the medium

- Overflow protection

- Leakage monitoring

- e.g. the AF001

- For detection through non-metal containers

- The cost-effective variant for point level monitoring

- e.g. the AC001 to AC005

- Adhesion ignored

- Level monitoring in tanks and containers

- Point level monitoring

- e.g. the AF005

- Adhesion ignored

- Level monitoring in tanks and containers

- Point level monitoring

- e.g. the AF006

Continuous level measuring

- Robust against adhesion and foam formation

- Probe can be shortened from 0.1 ... 1.6 m

- Specially developed for water-based media

- e.g. the AF003 and AF004

- Suitable for industrial applications

- Suitable for hygiene applications

- On tanks and in open water

- e.g. the AF901 to AF904

- e.g. the AP001 to AP022

- For large distances up to 10 m

- Without medium contact

- For bulk materials or non-transparent liquids

- e.g. the AL001 to AL004

- Contactless level monitoring

- Self-cleaning sensor membrane

- For levels of up to 8 metres in height

- e.g. the AU007

Sensors for limit detection/ sensors for continuous level measuring

Cloud compatible

Cloud compatible