Flush or non-flush for sensors

What is meant here by flush or non-flush?

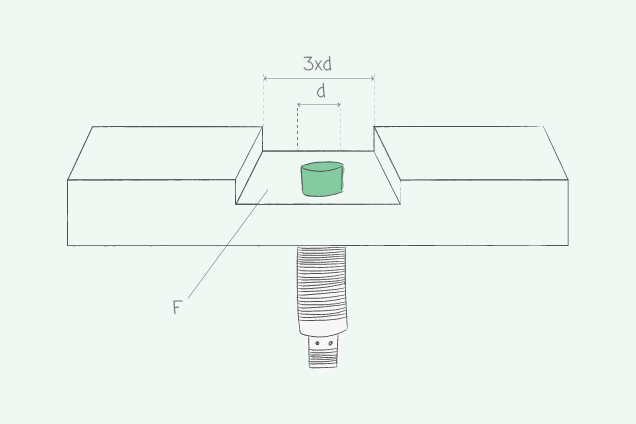

Flush / Non-flush (aka f / nf) are important details that appear in data sheets on inductive sensors. As the name indicates, flush-mountable sensors can be fully integrated into the surrounding metal up to the uppermost sensor face. Non-flush sensors, on the other hand, require some free space around the sensing face. Generally, non-flush sensors protrude a little from the surface. Manufacturers often clearly identify non-flush sensors with the aid of coloured caps. The thread ends below this cap, so the user can readily see that the sensor should not be completely recessed into the metal.

Non-flush sensors have the advantage of a larger sensing range because they need no shielding towards the exterior, so the sensing field can extend without restriction. However, many sensor purchasers still tend to buy flush devices because these can be fully recessed into the surrounding material, making them significantly less susceptible to accumulated dirt or mechanical damage. If you choose a non-flush sensor, you should bear the following installation conditions in mind:

Flush-mountable sensors can be fully integrated into the surrounding metal up to the uppermost sensor face. Non-flush sensors require some free space around the sensing face.

Patrick Targonski, Product manager at autosen

Non-flush installation

Non-flush sensors have the advantage of a larger sensing range because they need no shielding towards the exterior, so the sensing field can extend without restriction. However, many sensor purchasers still tend to buy flush devices because these can be fully recessed into the surrounding material, making them significantly less susceptible to accumulated dirt or mechanical damage. If you choose a non-flush sensor, you should bear the following installation conditions in mind:

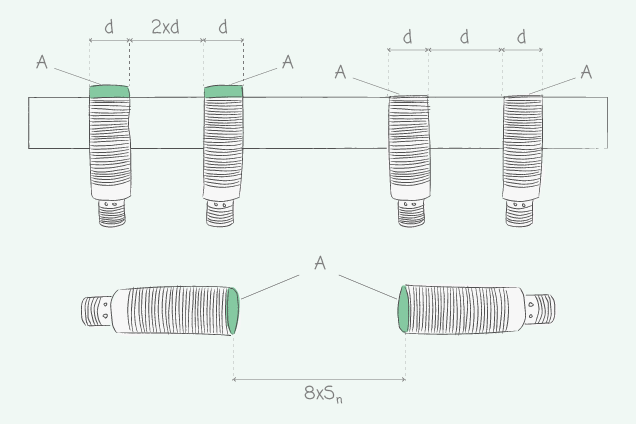

Mutual influence

If you wish to set up several proximity sensors of the same type close to each other, certain minimum distances between the devices should be maintained. These are illustrated by way of a rule of thumb in the following figure.