GS Laser Systems - Laser Tuning with Sensors

Precise, reliable and affordable

GS Laser Systems uses customised laser systems to turn the ideas of tradesmen, architects and designers into reality. The basic machines are procured on the world market, while the safety technology and sensors are 'Made in Germany'. The result is semi-automated, reliable and affordable precision technology.

On an industrial estate in the German city of Essen, GS Laser Systems produces state-of-the-art laser systems from globally procured components. These systems are then sold throughout Europe. The portfolio ranges from compact desktop devices for the fast engraving of various materials to high-performance systems with a particularly large working range or open portal models.

The majority of machines come from the Far East and are subject to a thorough overhaul, before being equipped with new control technology and then completely rebuilt for the European market according to strict European guidelines. This is followed by installation of the extraction and cooling technology and various attachment parts and accessories. There are practically no limits to the configurations, and some of the devices are individual custom-made products. The premium models also include sensor-based automation solutions that enhance the efficiency of the lasers.

Order, pick-up, assembly – all completed within half an hour!

David Geinitz, Managing Director

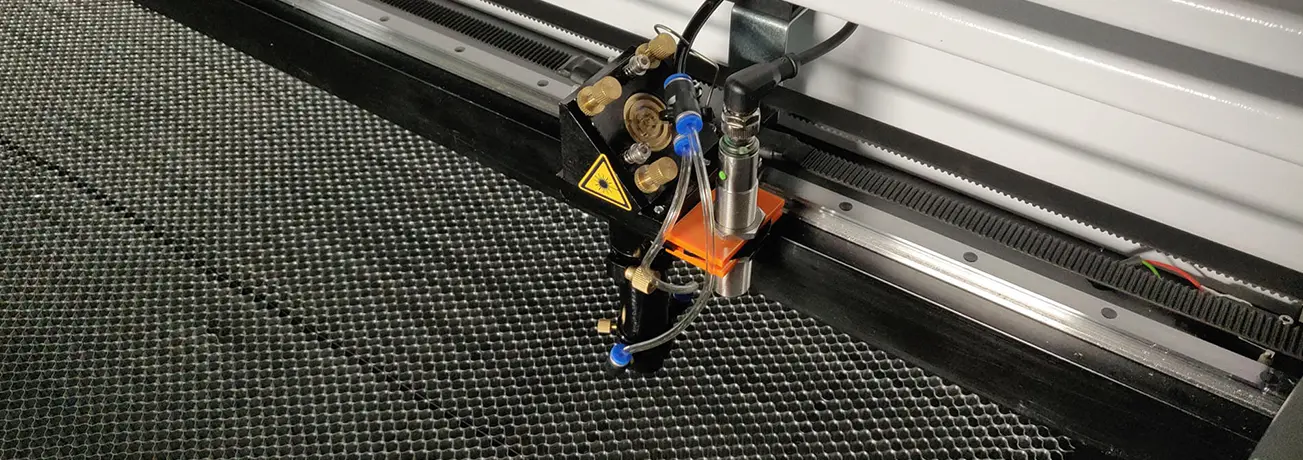

Automatic positioning of the workpiece

As a precision instrument, each and every laser has a narrow optimum working space. The decisive factor here is not the size of the working range but the actual distance to the workpiece, which is just a few millimetres. Even the slightest deviations can lead to a loss in quality and poor adherence to tolerances. Nevertheless, the height-adjustable working space is usually positioned manually.

GS Laser Systems relies on a semi-automated solution for this critical step. An autosen ultrasonic sensor AU004 on the laser head detects the height of the workpiece. As a result, laser placement can be reduced to two non-critical work steps: Positioning the material and raising the work surface. Once the exactly specified dimension has been reached, the sensor switches off the actuator relay – and the work surface stops moving automatically. This ensures correct positioning at all times, regardless of the thickness of the material, and thus the ideal working space for the laser.

Fast procurement – made even faster

GS Laser Systems exclusively uses autosen sensors in its machines. The decision in favour of autosen was made in part because of the simple and fast procurement process. Since time is a crucial factor for success in this industry. GS Laser Systems promises a response time within 24 hours and the delivery of spare parts within 48 hours in Germany. With no ifs, buts or maybes. The autosen sales model falls perfectly into this way of thinking: Order online and look forward to next-day delivery. It is extremely fast, but even that is sometimes not fast enough. In this case, David Geinitz, Managing Director of GS Laser Systems, jumps into his car after placing the order and picks up the spare parts himself.

Everything at a glance

GS Laser Systems produces state-of-the-art laser systems by re-engineering globally sourced basic machines.

The machines are equipped with safety technology and sensors from Germany to ensure a high level of precision and safety.

GS Laser Systems uses autosen sensors, including ultrasonic sensors, for semi-automated workpiece positioning solutions.

The autosen distribution model enables quick and easy procurement of spare parts, which is a critical factor of success for GS Laser Systems.

Manufacturer of laser machines

Lasertechnik Geinitz GmbH

Lierfeldstraße 49, 45326 Essen

info(at)gs-laser(dot)eu

info(at)gs-laser(dot)eu

+49 201 31919388

+49 201 31919388

www.gs-laser.eu

Products used

More success stories

Get started with the IIoT!

Very simple via io-key® wireless gateway Bring sensor data into the cloud

Cloud compatible

Cloud compatible